Copper Coil

Category:

WhatsApp:

Email:

Message

Product Description

In life, copper wire is used as a wire. Very good electrical conductivity, a large number of used in the manufacture of wires, cables, brushes, etc.; Good thermal conductivity, commonly used to manufacture magnetic instruments and meters that must prevent magnetic interference, such as compasses, aviation instruments, etc.; Excellent plasticity, easy to hot press and cold pressure processing, can be made into tubes, rods, wires, strips, strips, strips, plates, foils and other copper. Pure copper products have two types: smelted products and processed products.

|

Product Name |

Copper coil pipe ASTM B280 C12200 c2400 pancake copper coil tube air conditioning refrigeration copper coil pipes |

|

Surface |

Customers' requirement |

|

Material |

High Purity 99.9% Copper |

|

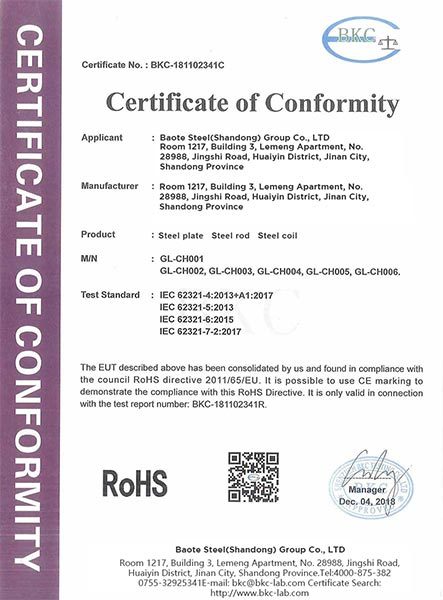

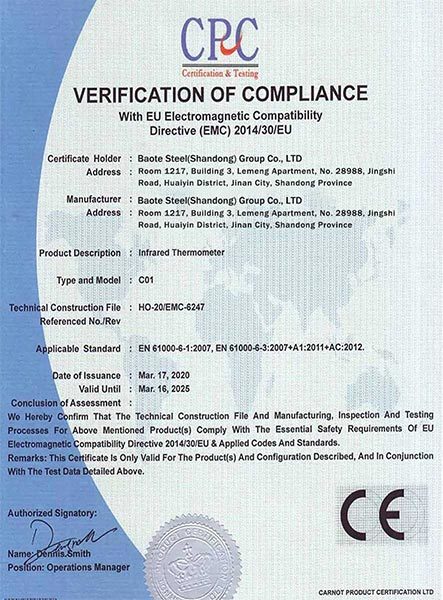

Certificate |

CE ISO |

|

Spangle |

Big Medium Small Zero |

|

MOQ |

25 Tons |

|

Thickness |

0.1-100mm or as required |

|

Payment term |

30%TT Advance + 70% Balance |

|

Package |

Standard Seaworth Packing |

Chemical composition

|

Cu+Ag: |

Sn: |

Zn: |

Pb: |

Ni: |

Fe: |

|

≥99.90 |

≤0.002 |

≤0.005 |

≤0.005 |

≤0.005 |

≤0.005 |

|

Sb: |

S: |

As: |

Bi: |

O: |

Impurities: |

|

≤0.002 |

≤0.005 |

≤0.002 |

≤0.001 |

≤0.06 |

≤0.1 |

Mechanical behavior

|

Tensile strength σb (MPa): |

Elongation δ10 (%): |

Elongation δ5 (%): |

|

≥275 |

≥5 |

≥10 |

Application scope

|

|

|

Power Industry: |

|

|

Electronics industry: |

Electric vacuum devices such as high-frequency and ultra-high-frequency launch tubes, transition tubes, magnetrons, etc., require high-purity oxygen-free copper and dispersion-strengthened oxygen-free copper. Copper printed circuits require large amounts of copper foil and copper-based soldering materials. In integrated circuits, copper is used as interconnects and lead frames instead of aluminum in silicon chips. |

|

Energy and petrochemical industry: |

The main condenser tube sheets and condenser tubes in thermal power plants in the energy industry are made of brass, bronze or cupronickel. Solar heaters are also often manufactured using copper tubing. Copper and many copper alloys in the petrochemical industry are widely used in the manufacture of various containers, piping systems, filters, pumps and valves, various evaporators, heat exchangers and condensers that are exposed to corrosive media. |

|

Transportation industry: |

In the shipbuilding industry, copper alloys include aluminum bronze, manganese bronze, aluminum brass, gun metal (tin-zinc bronze), white copper and nickel-copper alloy (Monel), etc., which are all standard materials for shipbuilding. In warships and merchant ships, copper and copper alloys are generally used as aluminum bronze propellers, bolts, condenser tubes, rivets, copper-containing coating paint, etc. In the automotive industry, copper and copper alloys are mainly used in radiators, brake system pipelines, hydraulic devices, gears, bearings, power distribution and power systems, brake pads, washers, and various joints, accessories and trims. Motors, rectifiers and control, braking, electrical and signaling systems on railway trains also rely on copper and copper alloys to work. In addition, the electrification of railways has created a large demand for copper and copper alloys. Copper is required for wiring, hydraulic, cooling and pneumatic systems in the aircraft, aluminum bronze tubes are used for bearing retainers and landing gear bearings, and antimagnetic copper alloy is used for navigation instruments. |

|

Mechanical and metallurgical industry: |

In addition to the large amount of copper used in motors, circuits, hydraulic systems, pneumatic systems and control systems, mechanical engineering also requires various transmission parts and fixing parts, such as cylinder liners, connectors, fasteners, gears, twisting parts, etc. Use copper or copper alloy to reduce wear and lubricate. |

|

Light industry: |

|

|

Emerging industries and high-tech fields: |

|

Factory Equipment

Application Area

Honors

Customer Photo

group photo

group photo

group photo

Related Products

MESSAGE