6063 Aluminum bar

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

Category:

WhatsApp:

Email:

Message

Product Description

6063 aluminum alloy material. The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy. 6063 aluminum alloy profile with its good plasticity, moderate heat treatment strength, good welding performance and anodic oxidation treatment, gorgeous surface color and many other advantages, is widely used in building profiles, irrigation pipes, for vehicles, platforms, furniture, elevators, fences and other tubes, bars, profiles.

6063 is a low alloyed Al-Mg-Si high plastic alloy. It has many valuable features: 1. Heat treatment, high impact toughness, not sensitive to the gap. 2. Excellent welding performance and corrosion resistance, no stress corrosion cracking tendency, in the heat treatment can be strengthened aluminum alloy, Al-Mg-Si alloy is the only alloy without stress corrosion cracking phenomenon. 3. After processing, the surface is very smooth and easy to anodize and color. Its disadvantage is that after quenching, if parked at room temperature for a period of time, the aging will bring adverse effects on the strength (parking effect).

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Surface Treatment: | Polished |

| Technique: | Cold Drawn |

| Hardness: | standard |

| Al (Min): | 99% |

| Material: | Aluminun |

| Temper: | T3 - T8 |

| Tolerance: | ±1% |

| Sample: | Avaliable |

| Application: | construction |

| Shape: | Round |

| Yield (≥ MPa): | 90 |

| Ultimate Strength (≥ MPa): | 30 |

| Processing Service: | Cutting |

| Surface: | Polished |

| Length: | 1m-6m |

| Package: | Standard Seaworthy Package |

| Standard: | ASTM AISI JIS DIN GB |

Mechanical behavior

|

Tensile strength (MPa) |

Yield strength (MPa) |

Hardness HB |

Elongation (%) |

|

228 |

193 |

60 |

12-20 |

Physical properties

|

Density |

Melting point |

Modulus of elasticity |

Thermal conductivity |

Resistivity |

|

2.68 Kg/m³ |

605 °C |

70 GPa |

138 W/m.K |

0.0495 x10^-6 Ω.m |

Annealing state

|

Trademark |

Annealing state |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Application scope

|

Aluminum uses and application areas |

|

|

Food packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Architecture |

Curtain walls, cladding, suspended ceilings, insulation, Venetian blinds etc. |

|

Transportation |

Auto parts, bus bodies, aviation ships and air cargo containers, etc. |

|

Electronic equipment |

Electrical appliances, communication equipment, PC board drilling guides, lighting and heat dissipation materials, etc. |

|

Consumer goods |

Parasols, cooking utensils, sports equipment, etc. |

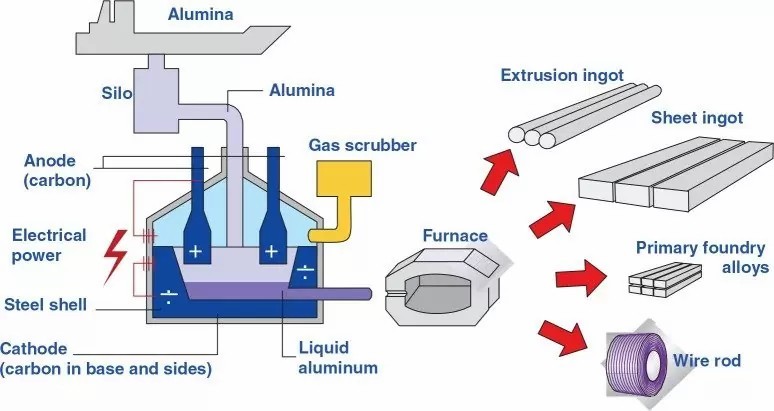

Aluminum Production Process

Packing and shipping

The company is located in the Free Trade Pilot Zone of Jinan City, Shandong Province, close to China's famous ports of Tianjin Port and Qingdao Port. It has a superior production and operation environment, convenient logistics exports, mature industrial facilities, and complete supporting industries.

Factory Equipment

Application Area

Honors

Customer Photo

group photo

group photo

group photo

Related Products

MESSAGE