Round Aluminum Sheet

MOQ: 2 Tons. Regular Delivery Time: 10-15 days.

Aluminum discs are widely used in electronics, daily chemicals, culture and education, insulation, machinery manufacturing, automotive, aerospace, military, mold, construction, printing and other industries.

Category:

WhatsApp:

Email:

Message

Product Description

Product Description:

Alloys: 1050/1060/1100/3003/3004/5005/5052/5083/3005/8011

MOQ: 2 Tons. Regular Delivery Time: 10-15 days.

Aluminum discs are widely used in electronics, daily chemicals, culture and education, insulation, machinery manufacturing, automotive, aerospace, military, mold, construction, printing and other industries. For example, the kitchenware like non-stick pans, pressure cookers, the hardware such as lamp- shades, water heater shells, traffic signs.

The features are:

*Low anisotropy which is ideal for deep drawing;

*Strong mechanical performance;

*Uniform heat conductivity;

*Easily to be coated and oxidized;

*High reflectivity rate;

*High strength-to-weight ratio;

*Strong oxidation resistance.

Our factory provides aluminum disc of various alloys, tempers, thicknesses and diameters to meet the needs of all customers.

Technical data

Technical Parameter:

| Parameter | Range | Tolerance | Alloy | Main Uses | Technology |

| Thickness(aluminum circle) | 0.2mm-5mm | for 0.71 to 1.4 +/-0.08 | 3xxx CC/DC | Cookware, Lamp | Anodizing, Enamel, Ceramics, Extruding, Ordinary Tensile |

| for 1.41 to 2.5 +0.1, -0.13 | 5xxx CC/DC | Cookware, Guidepost | Anodizing | ||

| for 2.51 to 4.0 +/-0.13 | 1xxx CC | Cookware, Lamp | Flow Forming, Ordinary Tensile | ||

| for 4.01 to 5.00 +/-0.15 | - | - | - | ||

| for 5.01 to 6.35 +/-0.20 | - | - | - | ||

| Thickness(Oval) | 1.75mm — 3.00mm | for 1.75 to 2.5 +0.1, -0.13 | |||

| for 2.51 to 3.00 +/-0.13 | |||||

| Diameter (mm) | 50—1500 |

(a)Cut circle diameter +2, -0 | |||

| (b)Deep drawing diameter +0.5, -0 | |||||

| Earing | <5% O <<9% H12,H14,H16,H18 |

- |

Mechanical behavior

|

Tensile strength (MPa) |

Yield strength (MPa) |

Hardness HB |

Elongation (%) |

|

228 |

193 |

60 |

12-20 |

Physical properties

|

Density |

Melting point |

Modulus of elasticity |

Thermal conductivity |

Resistivity |

|

2.68 Kg/m³ |

605 °C |

70 GPa |

138 W/m.K |

0.0495 x10^-6 Ω.m |

Annealing state

|

Trademark |

Annealing state |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Application scope

|

Aluminum uses and application areas |

|

|

Food packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Architecture |

Curtain walls, cladding, suspended ceilings, insulation, Venetian blinds etc. |

|

Transportation |

Auto parts, bus bodies, aviation ships and air cargo containers, etc. |

|

Electronic equipment |

Electrical appliances, communication equipment, PC board drilling guides, lighting and heat dissipation materials, etc. |

|

Consumer goods |

Parasols, cooking utensils, sports equipment, etc. |

|

Other |

Military, color-coated aluminum plate |

Packing and shipping

Factory Equipment

Application Area

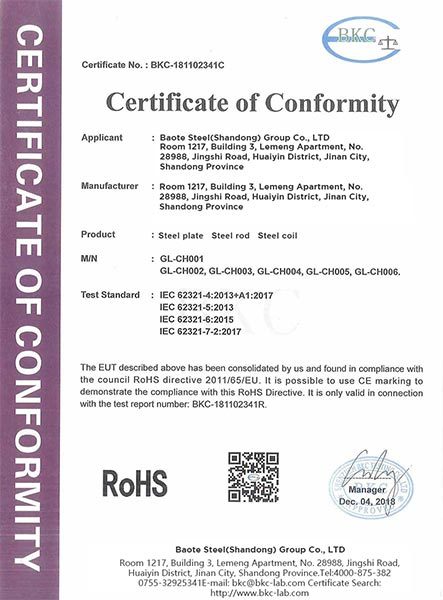

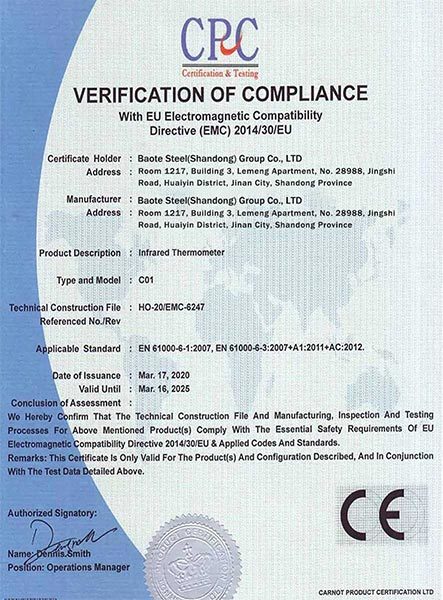

Honors

Customer Photo

group photo

group photo

group photo

Related Products

MESSAGE