DX52D Galvanized Round Steel

Category:

WhatsApp:

Email:

Message

Product Description

The construction industry is mainly used to manufacture anti-corrosion roof panels and roof gratings for industrial and civil buildings; In light industry, it is used to manufacture household appliance shells, civil chimneys, kitchen appliances, etc. In automobile industry, it is mainly used to manufacture corrosion resistant parts of cars, etc; Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, frozen processing tools for meat and aquatic products, etc; It is mainly used for the storage and transportation of materials and packaging tools.

Galvanized round steel is a geometric object made of iron or materials with certain strength and toughness by rolling, extruding, casting, hot galvanizing anti-corrosion profile surface and other processes. Hot dip galvanized round steel is produced by advanced galvanizing process, and its surface is glossy and durable. Galvanized round steel products have been used in many fields. The advantage of hot-dip galvanized round steel is that it has a long anti-corrosion life and has been a popular anti-corrosion treatment method to adapt to a wide range of environments. It is widely used in electric power tower, communication tower, railway, highway protection, street light pole, marine components, building steel structure components, substation ancillary facilities, light industry, etc.

|

Product name |

DX52D Galvanized Round Steel |

|

Diameter |

16-250mm or Customized |

|

Length |

Customized |

|

Advantages |

Dia< 10.00 mm, cold drawn, on request also ground; ISO h8 Dia > 10.00 mm, cold drawn, on request also ground; ISO h9 |

|

Finish Line |

Straightening machines |

|

Standard |

AiSi, ASTM, BS, GB, JIS, EN,AS ETC. |

|

Surface Treatment |

Galvanized |

|

Mechanical Property |

Delivery status: Tensile strength (Rm): 570 -820 MPa, size depending |

|

Bar Processing |

Heat treatment: soft annealing, normalising, isothermal, spheroidising and stress relieving treatments, quenching and tempering |

|

Application |

* Automatic lathe processing, metal stamping parts processing; |

Chemical composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

For cold forming Chinese standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

For cold forming Japanese standard |

SGCC |

0.15 |

0.50 |

0.80 |

0.050 |

0.030 |

0.025 |

|

SGCD1 |

0.12 |

0.50 |

0.60 |

0.040 |

0.030 |

0.025 |

|

|

SGCD3 |

0.08 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

SGCD4 |

0.06 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

For structure Japanese standard |

SGC340 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.025 |

|

SGC400 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.150 |

|

|

SGC490 |

0.30 |

0.50 |

2.00 |

0.200 |

0.035 |

0.025 |

|

|

SGC510 |

0.30 |

0.50 |

2.50 |

0.200 |

0.035 |

0.025 |

|

|

For structure AISI standard |

S220GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

S250GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S280GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S320GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S350GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

|

|

S550GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

Mechanical behavior

|

Grade |

Yield Strength MPa≥ |

Tensile strength MPa≥ |

Elongation A%≥ |

|

DX51D+Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D+Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D+Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D+Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD+Z/ZM/AM |

220 |

300 |

20 |

|

S250GD+Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD+Z/ZM/AM |

280 |

360 |

18 |

|

S300GD+AZ/AM |

300 |

380 |

18 |

|

S320GD+Z/ZM/AM |

320 |

390 |

17 |

|

S350GD+Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD+AZ/AM |

450 |

480 |

15 |

|

S550GD+Z/ZM/AZ/AM |

550 |

550 |

- |

Surface selection

|

Zero zinc flower |

Small zinc flower |

Normal zinc flower |

Big zinc flower |

|

|

|

|

|

Material comparison

|

Chinese standard |

Japanese standard |

European standard |

|

DX51D+Z/DC51D+Z (CR) |

SGCC |

DX51D+Z |

|

DX52D+Z/DC52D+Z |

SGCD1 |

DX52D+Z |

|

DX53D+Z/DC53D+Z/DX54D+Z/DC54D+Z |

SGCD2/SGCD3 |

DX53D+Z/DX54D+Z |

|

S220/250/280/320/350/550GD+Z |

SGC340/400/440/490/570 |

S220/250/280/320/350GD+Z |

|

DX51D+Z/DD51D+Z (HR) |

SGHC |

DX51D+Z |

Packing and shipping

The company is located in the Free Trade Pilot Zone of Jinan City, Shandong Province, close to China's famous ports of Tianjin Port and Qingdao Port. It has a superior production and operation environment, convenient logistics exports, mature industrial facilities, and complete supporting industries.

Factory Equipment

Application Area

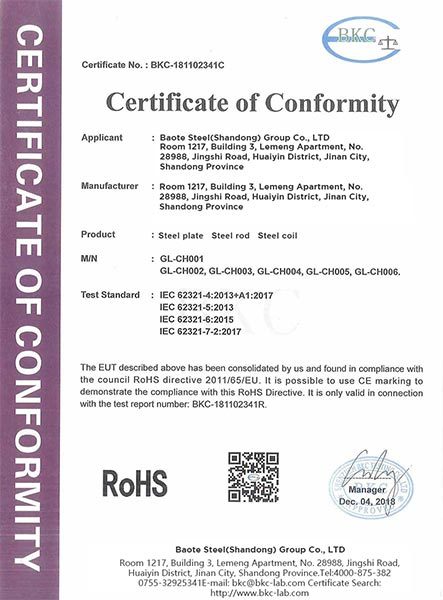

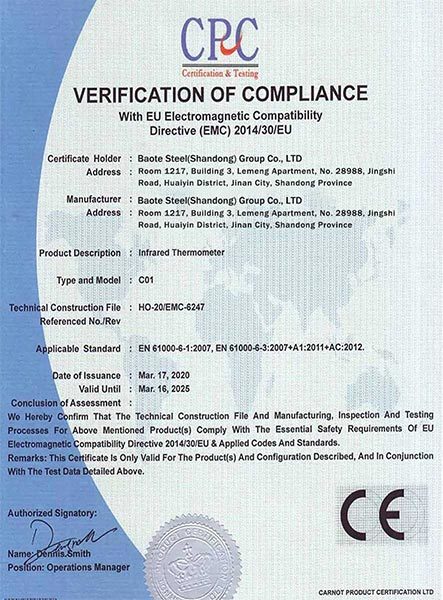

Honors

Customer Photo

group photo

group photo

group photo

Related Products

MESSAGE