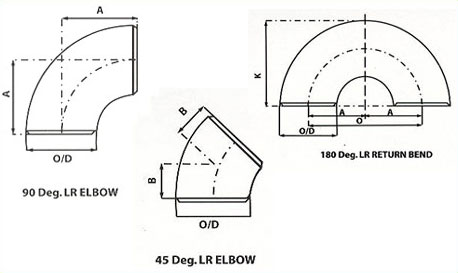

Steel Pipe Elbow

Category:

WhatsApp:

Email:

Message

Product Description

| Standard: | ASTM EN DIN GB ISO JIS | Certification: | SGS,ISO,ROHS |

| Length: | 1/2”NB to 48”NB | Process: | Drilling/Bending/Stamping |

| Diameter: | 15mm-6000mm | Technique: | Forged, Casting stainless steel flange |

| Pressure: | 150#-2500#,PN0.6-PN400、5K-40K,API 2000-15000 | Surface: | Rust-proof Oil,Black,Yellow |

| Wall thickness: | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60,SCH80, SCH160, XXS and etc. | Connection: | Welding, Threaded |

| Price terms: | FOB,CRF,CIF,EXW all acceptable | Payment Terms: | T/T, L/C at sight,West Union,D/P,D/A,Paypal |

| Type: | Plate,threaded,lip-on,socket welding,lap joint,blind,welding neckweld neck flange, slip on flange, blind flange, tube sheet, threaded flange,socket weld flange, plate flange, spectacle blind, LWN, orifice flange, anchor flange.(En1092-1 PN10 Pn16 DN900 DN750 Plate Steel Stainless Steel Flange) | ||

| Material: | Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H,A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo and etc. | ||

| Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 and etc. | |||

| Nickel alloy: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 etc.Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 etc. | |||

| Container Size: | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) | ||

Flange (flange is also called flange or flange.Pipe to pipe interconnection parts.Connect to the pipe end.Flanges have holes, can be threaded bolts, so that the two flanges are connected.The flanges are sealed with gaskets.Flanged pipe fittings refer to fittings with flanges (protruded edges or joints).It can be cast, threaded or welded.Flange joint is made up of a pair of flanges, a gasket and a number of bolts and nuts.The gasket is placed between the sealing surfaces of the two flanges. After tightening the nuts, the specific pressure on the surface of the gasket will be deformed when it reaches a certain value, and the uneven places on the sealing surface will be filled to ensure the connection is tight and leakless.Some pipe fittings and equipment have their own flange, also belongs to the flange connection.Flange connection is an important connection method in pipeline construction.

Flanged connection is easy to use and can withstand greater pressure.Flanged connection is widely used in industrial pipelines.In the home, the pipe diameter is small, and the pressure is low, the flange connection is not visible.If you're in a boiler room or production site, there are flanged pipes and equipment everywhere.

Generally speaking, the function of the flange is to make the connection of the pipe fixed and sealed.

Seamless Elbow Manufacturing Process (Heat Bending & Cold Bending)

One of the most common methods for manufacturing elbows is using hot mandrel bending from straight steel pipes. After heating the steel pipe at a elevated temperature, the pipe is pushed, expanded, bended by the inner tools of mandrel step by step. Applying hot mandrel bending can manufacture a wide size range seamless elbow. The characteristics of mandrel bending are strongely depend on the intergrated shape and dimensions of the mandrel. The using advantages of hot bending elbows include smaller thickness deviation and stronger bending radius than other bending methond type. Meanwhile, using bending instead of prefabricated bends substantially reduces the number of welds needed. This reduces the amount of work required and increases the quality and usability of pipes. However, cold bending is the process to bent the straight steel pipe at normal temperatures in a bending machine. Cold bending is suitable for pipes with an outer diameter of 17.0 to 219.1 mm, and wall thickness 2.0 to 28.0 mm. The recommended bending radius is 2.5 x Do. Normally at a bending radius of 40D. By using cold bending, we can get small radius elbows, but we need to pack the internals with sand to prevent wrinkling. Cold bending is a quick and inexpensive bending method. It is a competitive option for making pipelines and machine parts.

Welded Elbow Manufacturing Process (Small & Large)

Welded elbows are made from the steel plates, so it is not seamless steel elbows. Use a mould and press the steel plate to the shape of the elbow, then weld the seam to be a finish steel elbow. It is the old production method of the elbows. Recent years the small sizes elbows are almost manufactured from the steel pipes now. For the big size elbows, for example, it is very difficult to produce elbows over 36” OD from the steel pipes . So it is commonly made from the steel plates, pressing the plate to the shape of half elbow, and welding the two halves together. Since the elbows are welded in its body , the inspection of the welding joint is necessary . Commonly we use the X-Ray inspection as the NDT.

Factory Equipment

Application Area

Honors

Customer Photo

group photo

group photo

group photo

Related Products

MESSAGE