ultra-thin non-oriented and grain oriented electrical steel sheet

Category:

WhatsApp:

Email:

Message

Product Description

Product Introduction

ultra-thin non-oriented and grain oriented electrical steel sheet for transformer core silicon steel coilElectrical steel, also known as silicon steel, is a ferrosilicon soft magnetic alloy steel with very low carbon content, usually containing 0.5% to 4.5% silicon. The addition of silicon can increase the resistivity and maximum permeability of iron, and reduce the coercivity, iron loss and magnetic aging.

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, its grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually cold-rolled plates or strips, which are mainly used to manufacture motors and generators. Oriented silicon steel: It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N).

Specifications

| Product Name | Electrical Steel, Lamination Steel, Silicon Electrical Steel, Silicon Steel, Relay Steel, Transformer Steel |

| Category | Grain-Oriented Electrical Steel;聽Non-oriented electrical steel |

| Standard | AISI, ASTM, BS, DIN, GB, JIS, EN |

| Thickness | 0.27- 0.50 mm |

| Width | 900-1230 mm |

| Brand | Gnee |

| Origin | China |

Product Advantages

1.Stable performance

2.Excellent processing performance: High precision dimension and excellent mechanical properties make it easy to be sheared, punched and stacked by high speed punch machine. It also have good welding performance.

3.Excellent performance of Insulating coating: Uniform color, good insulation, high adhesion, excellent heat resistance and excellent processing performance

Mechanical Property

| Strength | Ultra | Ductility | Hardness | |

| (N/mm2) | -Tension | (%) | (HV1 | |

| Strength | ||||

| (N/mm2) | ||||

| M35W230 | 430 | 560 | 20 | 225 |

| M35W250 | 415 | 550 | 20.5 | 220 |

| M35W270 | 400 | 515 | 20.5 | 215 |

| M35W300 | 360 | 480 | 21.5 | 195 |

| M35W360 | 350 | 480 | 23.5 | 190 |

| M35W440 | 275 | 420 | 27.5 | 165 |

| M35W550 | 265 | 415 | 33.5 | 160 |

| M50W250 | 430 | 560 | 19 | 230 |

| M50W270 | 410 | 550 | 21.5 | 225 |

| M50W290 | 395 | 545 | 22.5 | 220 |

| M50W310 | 385 | 510 | 24.5 | 210 |

| M50W350 | 350 | 475 | 26.5 | 190 |

| M50W400 | 320 | 460 | 36 | 170 |

| M50W470 | 295 | 425 | 35 | 160 |

| M50W600 | 280 | 410 | 37 | 140 |

| M50W800 | 285 | 405 | 38.5 | 135 |

| M50W1300(D) | 250 | 360 | 40 | 11 |

Insulating Coating

| Coating types | M11 | M21 |

| Component | Chromium containing , semi organic coating | Chromium free, semi organic coating |

| Coating thickness | 0.7~1.5 | 0.8~5.0 |

| (μm) | ||

| Interlayer resistance | ≥100 | ≥100 |

| (Ω•mm2 /slice) | ||

| Adhesive property | Class A or class B | Class A or class B |

| Punching property | Excellent | Excellent |

| Antirust property | Excellent | Excellent |

| Heat resisting property | Resistant annealing at 750 C, N2 protection, for 2h | Annealing resistance in general |

Product Application

| Field | Purpose |

| Rotary machine | Large motor |

| Medium motor | |

| Compressor motor | |

| General Motors | |

| Small precision motor | |

| Motor for electric vehicle | |

| The Immobilizer | High frequency working motor |

| Miniature power supply transformer | |

| Instrument use transformer | |

| Reactor | |

| Welding machine use transformer | |

| Power switch | |

| Manostat | |

| Magnetic sealing unit | |

| Electromagnet for accelerator |

Product parameters

|

Category |

Silicon content/% |

Nominal thickness/mm |

The main purpose |

||

|

Hot rolled silicon steel (non-oriented) |

Hot rolled silicon steel (non-oriented) |

1.0~2.5 |

0.5 |

Household motors and micromotors |

|

|

Hot rolled high silicon steel (transformer steel) |

3.0~4.5 |

0.35、0.50 |

Transformer |

||

|

Cold rolled electrical steel |

Cold rolled non-oriented electrical steel (motor steel) |

Low carbon electrical steel |

≤0.5 |

0.50、0.65 |

Household motors, micromotors, small transformers and ballasts |

|

Silicon steel |

>0.5~3.5 |

0.35、0.50 |

Large and medium-sized motors, generators and transformers |

||

|

Cold-rolled oriented silicon steel (transformer steel) |

Ordinary oriented silicon steel |

2.9~3.3 |

0.18、0.23、0.27 |

Large, medium and small transformers and ballasts |

|

|

High magnetic induction oriented silicon steel |

|||||

|

Special purpose silicon steel |

Cold rolled oriented silicon steel strip |

2.9~3.3 |

0.03、0.05、0.10 |

Pulse transformers, magnetic amplifiers, high frequency transformers and welding machines |

|

|

Cold rolled non-oriented silicon steel strip |

3.0 |

0.15、0.20 |

High frequency motors and generators |

||

|

Cold-rolled non-oriented silicon steel for magnetic switches |

3.0 |

0.70 |

Relays and magnetic switches |

||

|

Cold rolled high silicon steel |

6.5 |

0.1~0.5 |

High frequency motors, transformers and magnetic shielding |

||

Packing and shipping

The company is located in the Free Trade Pilot Zone of Jinan City, Shandong Province, close to China's famous ports of Tianjin Port and Qingdao Port. It has a superior production and operation environment, convenient logistics exports, mature industrial facilities, and complete supporting industries.

Factory Equipment

Application Area

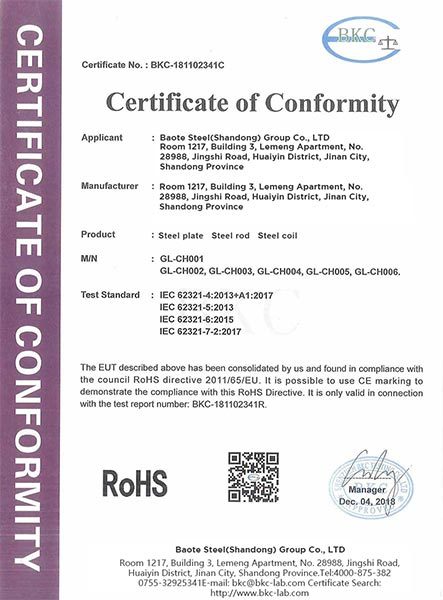

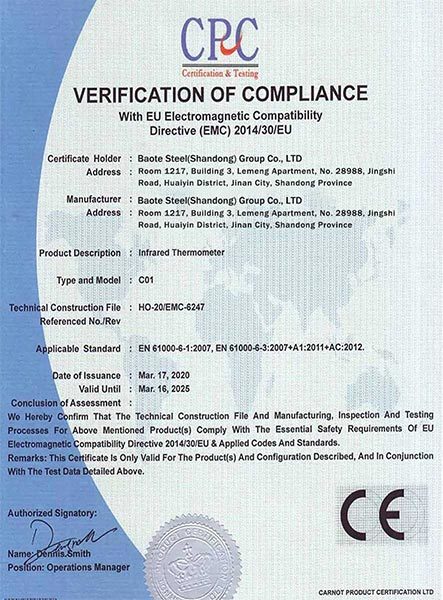

Honors

Customer Photo

group photo

group photo

group photo

Related Products

MESSAGE