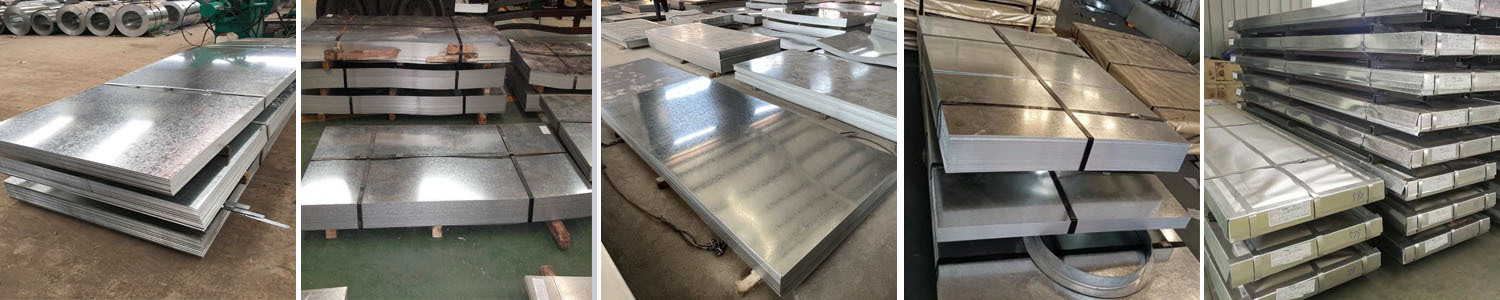

DX51D Galvanized sheet

Category:

WhatsApp:

Email:

Message

Product Description

Dx51d galvanized sheet material is a non-ferrous alloy mainly composed of zinc as the matrix and other elements. The main alloy elements are aluminum, copper, magnesium, etc. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and is resistant to atmospheric corrosion. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The commonly used cast zinc alloy is zinc aluminum copper magnesium alloy. Its casting process performance is good, and the cooling rate has little impact on the mechanical properties. It is mainly used to manufacture mechanical parts, toys, decorations, household appliances, etc. The commonly used wrought zinc alloys are zinc aluminum alloy and zinc copper alloy. The former contains 4%~15% aluminum. In order to improve the strength and hardness of the alloy, a small amount of copper, magnesium and other alloy elements are added. It has high strength and is easy to form. It can replace some brass or duralumin to make precision forgings. The latter is 0.7%~1.5% copper, which can increase the strength and impact toughness of the alloy and reduce the plasticity. Zinc copper alloy is suitable for making daily hardware products or replacing part of brass.

|

Product name |

DX51D Galvanized steel sheet |

|

Standard |

ASTM,DIN,JIS,BS,GB/T,GB,EN |

|

Material |

DX51D |

|

Application |

Villas ,townhouse, apartments ,tourist destination building ,and roof conversion project |

|

Thick |

0.12-4.0 mm / BWG / AWG or as your request |

|

Width |

20-1500 mm or as your request, Normal width is 914/1000/1219/1250/1500 mm |

|

Zinc Coating |

30~600 G/M2 |

|

Surface Structure |

Regular spangle,Minimum spangle, Zero spangle, Big spangle |

|

Surface Treatment |

Chromated/Non-Chromated, Oiled/Non-oiled, Skin pass |

|

Package |

Waterproof paper & plastic film & iron packing & bunding, or as customer's requirement |

Chemical composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

For cold forming Chinese standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

For cold forming Japanese standard |

SGCC |

0.15 |

0.50 |

0.80 |

0.050 |

0.030 |

0.025 |

|

SGCD1 |

0.12 |

0.50 |

0.60 |

0.040 |

0.030 |

0.025 |

|

|

SGCD3 |

0.08 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

SGCD4 |

0.06 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

For structure Japanese standard |

SGC340 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.025 |

|

SGC400 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.150 |

|

|

SGC490 |

0.30 |

0.50 |

2.00 |

0.200 |

0.035 |

0.025 |

|

|

SGC510 |

0.30 |

0.50 |

2.50 |

0.200 |

0.035 |

0.025 |

|

|

For structure AISI standard

|

S220GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

S250GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S280GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S320GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S350GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

|

|

S550GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

Mechanical behavior

|

Grade |

Yield strength MPa≥ |

Tensile strength MPa≥ |

Elongation A%≥ |

|

DX51D+Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D+Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D+Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D+Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD+Z/ZM/AM |

220 |

300 |

20 |

|

S250GD+Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD+Z/ZM/AM |

280 |

360 |

18 |

|

S300GD+AZ/AM |

300 |

380 |

18 |

|

S320GD+Z/ZM/AM |

320 |

390 |

17 |

|

S350GD+Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD+AZ/AM |

450 |

480 |

15 |

|

S550GD+Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized surface options

|

Zero zinc flower |

Small zinc flower |

Normal zinc flower |

Big zinc flower |

|

|

|

|

|

Packing and shipping

The company is located in the Free Trade Pilot Zone of Jinan City, Shandong Province, close to China's famous ports of Tianjin Port and Qingdao Port. It has a superior production and operation environment, convenient logistics exports, mature industrial facilities, and complete supporting industries.

Factory Equipment

Application Area

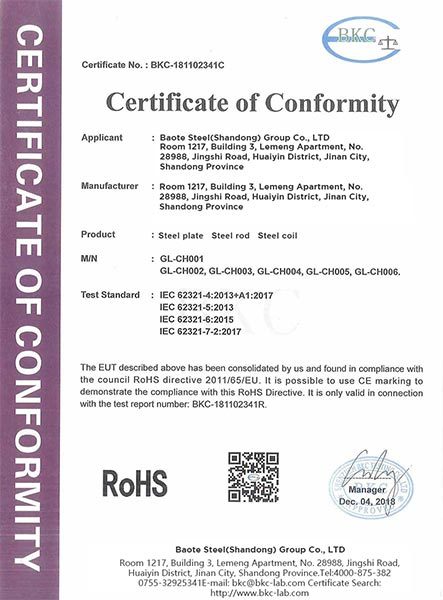

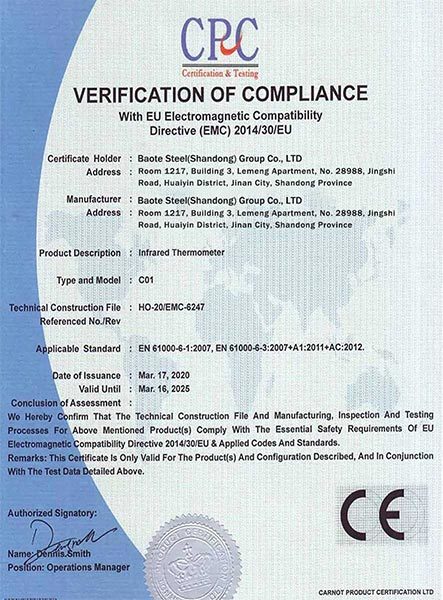

Honors

Customer Photo

group photo

group photo

group photo

Related Products

MESSAGE